Branched polymers have attracted increasing interest due to their numerous and various applications originating from a large variety of available polymer topologies compositions or morphologies for phase separating systems as emulsifier and interfacial compatibilizers or for surface modification properties.

Branched vinyl polymers.

Branched polymers of styrene methyl methacrylate mma and vinyl acetate vac were prepared under solvent free conditions through radical polymerization in the presence of a peroxide monomer.

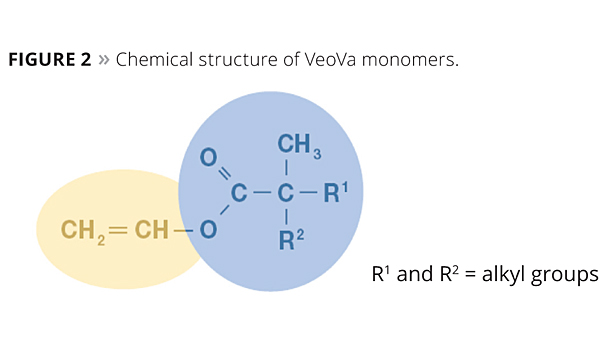

Veova vinyl esters have unique highly branched aliphatic structures which contribute to the enhancement of key polymer performance properties.

Macromolecules 2009 42 20 7745 7752.

Application of the strathclyde route to branched vinyl polymers in suspension polymerization.

Veova vinyl esters are commonly used in vinyl acetate and acrylic polymers where they greatly improve hydrolytic stability adhesion water and uv resistance.

Graft copolymers 1 4 are one of the important classes of branched polymers and.

Architectural thermal and rheological characterization of the derived branched products.

For those reactions with 1 mol crosslinker and no thiol the reactions gelled.

Synthesis of branched vinyl polymer using a balance of crosslinker and radical transfer agent.

Furthermore radical polymerization in the presence of the peroxide monomer can be operated in a simple polymerization composition involving only the.

Also discovered is a vinyl polymer resin comprised of from 0 1 to 50 weight percent of non linear polymers having at least 0 06 branches 1000 backbone carbons where branching is measured using a heat polymerized polystyrene having from 0 0 to 0 06 branches 1000 backbone carbons as a linear reference.

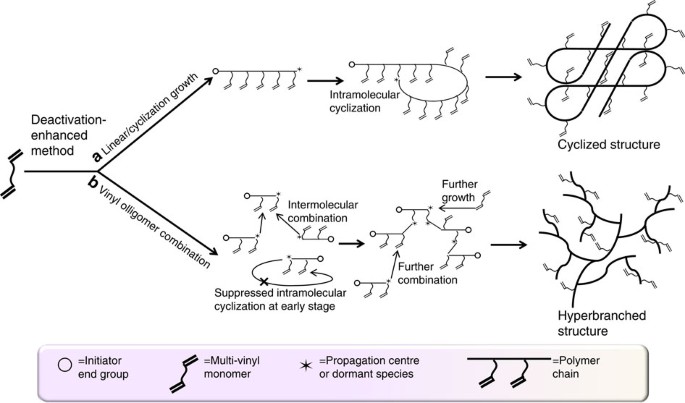

Reported the preparation of branched vinyl polymer through self condensing vinyl polymerization of an inimer scvp.

In addition the zimm branching factor g.

An approach to branched vinyl polymers through radical polymerization in the presence of 3 mercaptohexyl methacrylate mhm as the chain transfer monomer is reported in this paper.

Manufacturing of vinyl acetate veova vinyl ester polymers is easy due to the favorable reactivity characteristics of the veova monomer and vinyl acetate.

Copolymerisations of mma and bda were carried out in toluene solution under vacuum at 80 c using a standard methodology.

The copolymerization of hydrophobic vinyl ester of branched neo carboxylic acids significantly improves the performance of vinyl and acrylic binders.

Table 1 summarises the results obtained.